Highly effective technology for colouring asphalt

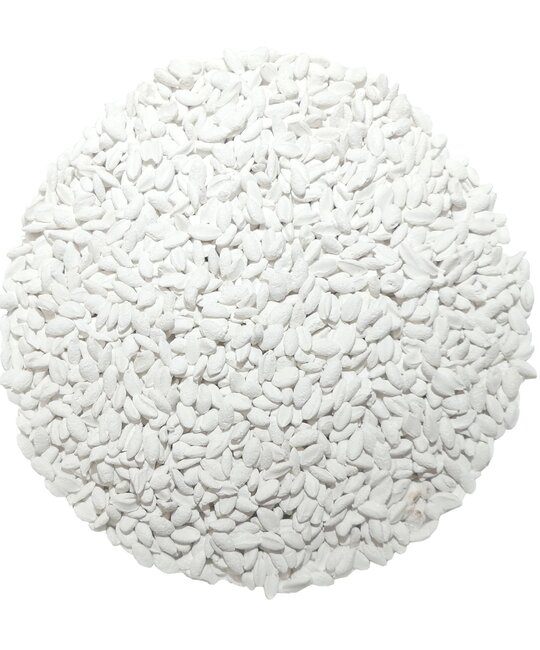

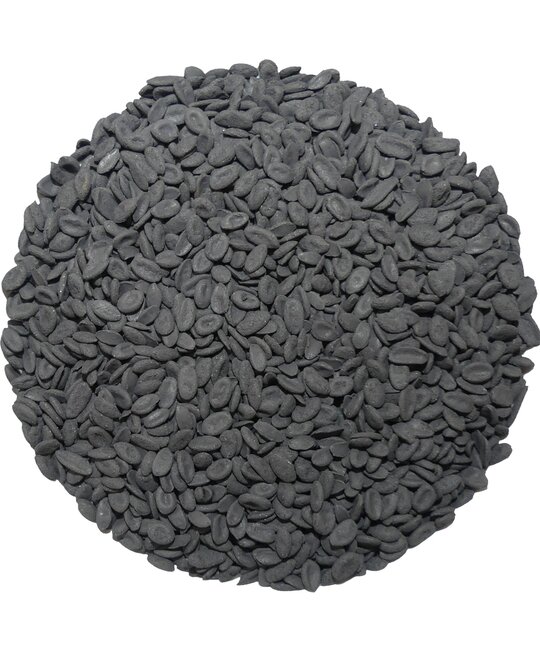

PEP (Polymer Encapsulated Pigment) represents a new generation pigment designed specifically for tinting road asphalt.

It consists of pigment encapsulated and pre-dispersed in a polymer master batch.

This novel pigment formulation brings significant improvements to the performance and implementation of colored asphalt manufacturing processes.

Why PEP?

Verified technology

- since 1999 developed and tested

Simply application

- Optimized simply and effective dosage of granulate into the asphalt mix

Unique

Outperform traditional colouring of asphalt by powders both in application and final colour performance

Authentic

Can be designed to then needs of designer idea & easy and economically used by experts in the field

Benefits

A great variety of colors available ‘on demand’

Compatible with Organic pigments

Specifically developed for the roadbuilding industry

Enhances the strength of asphalt

Totally dust free (clean)

Better dispersion à high coloring strength

Easy to dose and easy to apply

Remains stable when stored according SDS

Waterproof

Mixing

PEP-Red is the most used colour in the roadbuilding industry. Red pigments are typically used with black bitumen, while other colours are recommended for use with synthetic binders to achieve optimal results.

- PEP Red contains 20% of polymer binder + 80% pigment

With black binder

- ONLY PEP RED

- 2,0-5,0% to asphalt mixture

With clear binder

- ALL COLOURS

- 0,5-2,0% to clear binder mixture

Transport

- Material is supply in thermal melting bags 10, 25kG or big bag 1000kg

- Each pallet has 1000kg of total material weight

- PEP melting temperature is 90-120 ⁰C

Dosing and temperature

- Automatic or manual dosing

- Dosing of PEP together with or directly after bitumen binder

- The same mixing temperature (160-180℃)

- Longer mixing (10-50 seconds longer)

CZ

CZ